Other Polymer

Home Other Polymer

Home Other Polymer

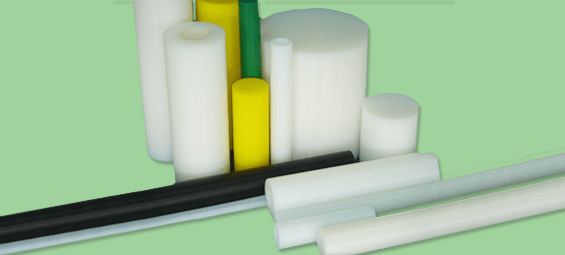

POLYURETHANE : Polyurethanes are cost effective and dependable Elastomers that combine the performance advantages of engineering plastics, metals and ceramics along with the resiliency and flexibility of rubber. These are internationally popular for their high load bearing capacity, high impact strength, high abrasion resistance, high resilience and excellent resistance to oil and grease.

NYLON : Polyamide, one of the most widely used engineering thermoplastics, is an extremely versatile engineering plastic. An excellent combination of mechanical performance (toughness, low coefficient of friction, and good abrasion resistance) and low cost to make is an ideal replacement for a wide variety of materials from metal to rubber. Cast Nylon 6 (polycaprolactam) exhibits all the properties that generally make Polyamide a superior engineering material: high strength, low friction and wear resistance. Because of the casting process, part size and thickness are almost unlimited without degradation of the material’s internal structure. Cast Nylon 6 provides one of the largest array of sizes and custom shapes of any thermoplastic.

POLYPROPYLENE (PP) : Friction surface, all of which make it ideal as a replacement for wood or metal which are the materials traditionally used. PP is a high corrosion resistant material, which exhibits excellent tensile strength and stiffness at elevated temperatures.

POLY VINYL CHLORIDE (PVC) : Our range of extruded PVC sheets is light in weight with homogeneous close cell structure that makes them highly durable. Highly resistant to chemical, these products are extensively used in process industries and laboratories. We also offer our customer cost effective customization of PVC sheets exactly as per their requirement. Ideal for chemical process industries and laboratories and are used for fabrication and lining.

POLYACETAL : Polyacetal sheets & rods are among the strongest and stiffest of all thermoplastics. Polyacetal and Delrin® plastic materials are characterized by good fatigue life, low moisture sensitivity, and high resistance to solvents and chemicals. Polyacetal products also contain good electrical properties.

HIGH DENSITY POLY ETHYLENE (HDPE) : HDPE Rod is a FDA Approved material of the highest quality with excellent impact resistance. HDPE has high tensile strength, low moisture absorption and is chemical and corrosion resistant. It is a light weight material that is non-toxic and non-staining and used in a variety of applications and industries. HDPE materials are available in both rod and sheet.

ULTRA HIGH MOLECULAR WEIGHT POLYETHYLENE (UHMW) : Ultra High Molecular Weight Polyethylene provides superior resistance to corrosion from chemicals and abrasive environments like sand and slurries when compared to other thermoplastics. It also offers exceptional impact resistance, even at cryogenic temperatures and is superior to stainless steel. The most important characteristics of UHMWPE include low moisture absorption, good electrical and thermal insulation.

BAKELITE : Bakelite rods, sheets and profiles that can be used both alone, to form whole objects, and in combination with other materials, use as laminate or surface coating. It is used as a substitute for hard rubber, amber or celluloid, for insulating electrical apparatus (as it is a nonconductor), and for the production of certain machinery gears, phonograph records, and various other articles.